All you need to know for estimating resin volume and printing time in Lychee Slicer

You may have noticed that sometimes (or often!), the printing time estimated by Lychee Slicer can be inaccurate compared to what the timer on your 3D printer reads at the end of the print. You might also notice a difference in the estimated volume of resin and what is needed to complete a print. Let’s talk about both issues to understand the cause of the variance and help you anticipate or improve the result you have.

Print time estimation

Print time estimates can be tricky because they depend on the 3D printer you are using and also the settings that you’re able to input for it’s 3D printing parameters.

Single-stage or two-stage build plate movements

Some printers use a single-stage movement when lifting the build plate: it’s a constant movement rate up and down, with only a slight acceleration and deceleration. This one is easy to calculate.

Other printers use a two-stage movement, starting slow then accelerating rapidly.

For some printers, this setting can be adjusted in the printing parameters … but for others it’s set by the firmware without user control of these settings (distance, speed, and more). Two-stage movement can be a more challenging calculation.

The math behind the estimate

So, how does Lychee Slicer attempt to calculate the estimated printing time? For simplicity, let’s consider only regular layers.

For single-stage movement, the time estimation is:

- The exposure time plus,

- The lift distance multiplied by the lift speed value plus,

- The same operation with the lowering values plus,

- If you set it, the light-off delay time,

- Finally, multiplied by the total number of layers and you have the print time estimate.

When the printer is using a two-stage movement, things can get complicated. If a printer lets you enter the settings for distance and speed of the two-stage segments, the same calculation as the one-stage movement is done, except it becomes four steps (two “up” and two “down”), not just two.

The two-stage problem

Some two-stage movement 3D printers affect the time estimation of the slicer with imprecise two-stage speed and distance values.

Some 3D printers accept user input to define the speed and distance for both stages. In these cases, our time estimation is usually spot-on.

However, for some two-stage printers, the user can only enter a single-speed and distance value for the two-stage movement. The 3D printer firmware is then calculating the first (slower) stage in the process, and we don’t know the precise formula for this calculation.

Most 3D printer manufacturers don’t have this formula to share. It is known only by the motherboard manufacturer of the printer.

Of course, we’ve tried to decipher the formula with our own printers, trying to find something that may help. We’ve filmed the bed movements at a high frame rate while precisely timing the moves, but ultimately nothing reliable enough to share was gleaned.

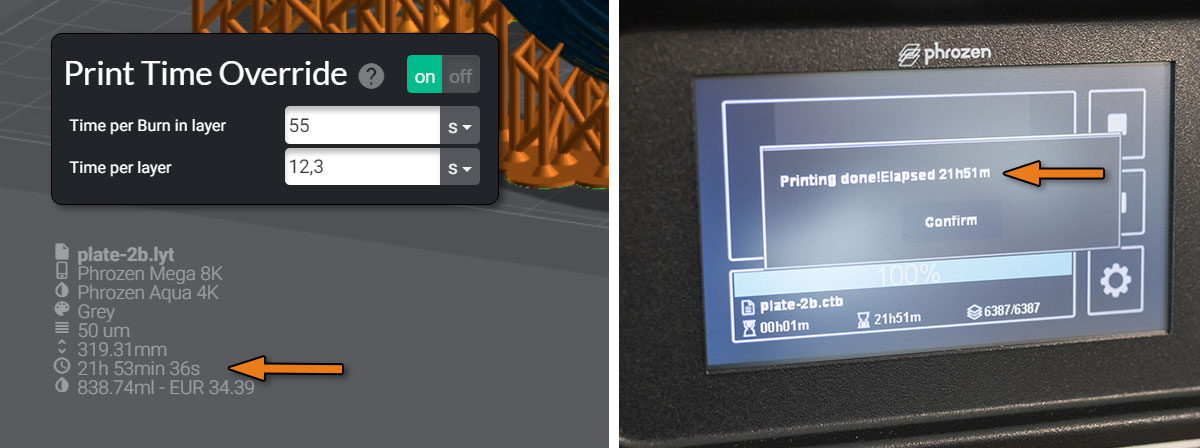

With Print Time Override, found in the resin settings, you can define the (actual) time it takes to print a layer, giving you a much more accurate time estimate. In this example, Lychee Slicer estimated the print time at 21h53m, and it finished at 21h51m. Very close!

The solutions

There are two solutions (so far), one that can help you right away and another that will depend on firmware and file formats that we support in Lychee Slicer.

First, there is a tool in Lychee Slicer called Print Time Override. This feature lets the user input the precise time required to print one (regular) layer. This feature is easy to use and allows a very accurate time estimation for your prints. We invite you to read this short article that walks through the process!

The second solution depends on the age and brand of your 3D printer. If the printer runs on a Chitu Systems motherboard capable of receiving a firmware update, a new CTB file format supports these two-stage settings. Once we (receive access) fully support this file format, the users of these printers with an updated motherboard should have a much more accurate time estimation.

All that remains is a group of 3D printers that may not have a good time estimation for some time still, as we might never have the math behind their two-stage process, like recent Anycubic printers. If you have the information, let us know! For these printers, the first solution remains the best one!

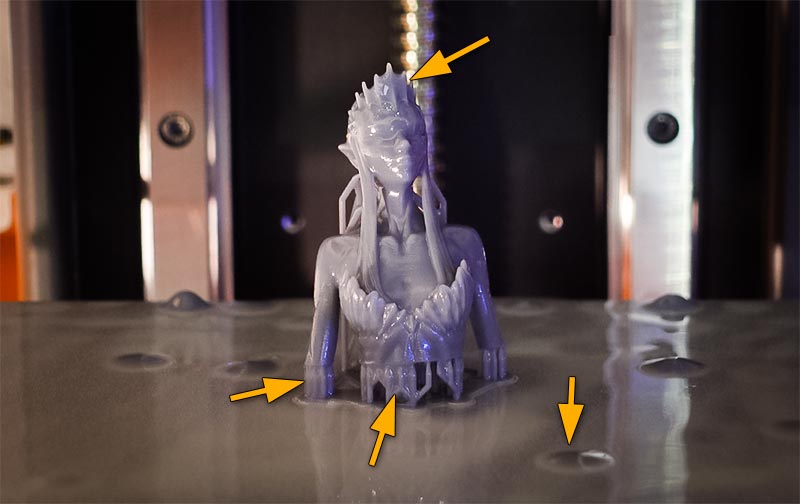

Above; a failed print due to an empty resin vat. Even with accurate estimates, prints can fail when we’re a few min late to refill the reservoir! 3D model: A2 by Arkey

Resin volume estimates

We regularly receive messages from the community informing us our resin estimation is completely off* because a print failed when their vat ran dry. They even put a bit of extra resin compared to what the software was estimating.

Our resin volume estimation in Lychee Slicer, it turns out, is extremely precise. We compute each pixel size of the sliced files by their thickness. Nothing can be more accurate! Of course, we also perform thorough comparisons with the volume estimates across multiple programs, and each time we confirm the accuracy of our slicer’s estimates.

Then why such a difference? Why do people still run out? There are multiple reasons.

Extra resin everywhere… and more than you know!

Residual resin on the surface of the model

Residual resin is one of the main issues creating a discrepancy in volume estimates and reality! A lot of resin remains on the surface of your printed model and on the build plate itself.

Different resins are more or less fluid, but they will all cling to your print to some degree. This volume of resin left on each surface is often much more significant than we realize. With bigger models, the amount of resin clinging to these surfaces can be exponentially greater than on a smaller model.

Piling on to these conditions, if your model is hollowed or has a lot of supports and bracing, the total surface area where resin can remain is significantly larger.

Then if we consider these factors combined with a resin that happens to be quite thick and viscous, the quantity of residual resin is even higher.

The larger the model, the more residual resin you will have on the surface of the model. Particularly common on the supports and the bracing. Model: A2 by Arkey

Resin trapped in small (or large) cavities

Because of resin’s viscosity, if your model has many small cavities created by: the detail, crowded supports, supports very close to the model, or dense bracing resin will get trapped in any or all of these areas.

For small miniatures with few supports, the quantity of resin clinging to cavities may be trivial. With larger models, it can be a surprisingly large volume.

In some cases, large cavities that you may not have noticed with hollowed models don’t receive adequate (or any!) drain holes and can retain a lot of uncured resin.

The solution with a bit of advice

Even attempting to reverse engineer the quantity used by measuring the remaining resin in the printer vat is difficult due to volume loss in the transfer process. Resin viscosity will vary between brands, but the inherent thickness makes it difficult to estimate the quantity needed for a print.

The safest solution is to multiply the volume estimation by a value based on each model, like 20% extra for a small print and 40% more for a larger print. Even then, a fixed value may not be enough, as each print may have unique qualities to add to the volume estimation.

Finally, please remember that you must have enough resin in your tank to maintain at least 5mm of resin in the tank available for curing, even with a perfectly leveled printer.

When the peeling process occurs, you need to have enough resin to fill the gap left by the previous layer, especially with larger-sized prints. If you don’t have enough to fill that gap, you can end up with a print failure.

Our best advice is simple, pour more than enough resin in your resin tank, err’ on the side of caution, and always use the resin volume estimation as an approximate value to determine the volume and cost of your prints.

Lychee Slicer 3.5 is now available for all users of the application, either as a free version or with a Pro subscription. Download the latest version from our download center or directly from the software.

Join our community now on our Discord server. It’s free and we are already several thousand to exchange and share around 3D printing with Lychee Slicer.

A wonderful product made with passion by